- info@matltech.com

- Global Center, No.1700 Tianfu Avenue Septentrionalis, Chengdu 610041, China.

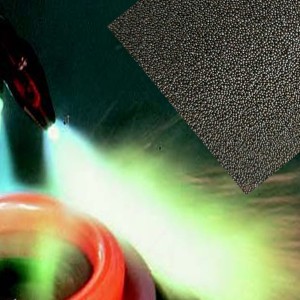

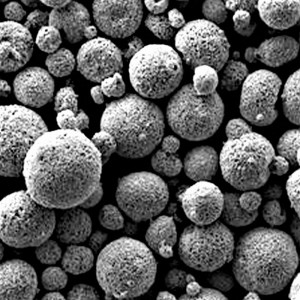

Conglutinata Carbide Hardsurfacing Powder

Descriptio

Conglutinata Carbide dura surfacing pulveris, inter Tungsteni Carbide fundatum seu Chromium Carbide fundatum in pulvere Thermal spargens (TSP), esse sphaericam vel fere sphericam cinerei grisei cum bono fluxabili, processit in lineamentis agglomeratis et sinteratis (A+S) vel sinteratis et contusis (S+C), in proprietates singulares sicut resistentia abrasionis bona, resistentia corrosio et resistentia calidissima, maxima temperatura operans carbidi turgi innixa est circiter 500°C, chromium carbidi subnixum est circiter DCC°C-870°C.Carbide dura-surfacing pulveris vel Tungsten Carbide dura-surfacing Pulvis vel Thermal spargens pulverem variis generibus spargit et plasma spargit glutino etc in fodienda, petrolei, metallurgicae industriae, machinae agriculturae, chalybe et industriae constructionis.

Delivery

Conglutinata Carbide Hard-surfacing Pulvis apud Minmetales occidentales (SC) Corporatio cum Wolframi Carbide liberari potest ut WC-12Co, WC-17Co, WC-10Co4Cr, WC-10Ni, WC-12Ni, WC-17Ni, WC-15NiCr etc. et Chromium Carbide innititur ut Cr3C2-20NiCr, Cr3C2-25NiCr etc in magnitudine 10-30um, 10-45um, 20-59um pulveris etc, sarcina 25kg in sacculo plastico cum tympano ferreo extra.

Singula

Tags

Technical Specification

Conglutinata Carbide dura surfacing pulverisseu Powder Thermal spargens in Minmetalis occidentalis (SC) Corporatio cum Wolframi Carbide liberari potest ut WC-12Co, WC-17Co, WC-10Co4Cr, WC-10Ni, WC-12Ni, WC-17Ni, WC-15NiCr etc et Chromium. Carbide innititur ut Cr3C2-20NiCr, Cr3C2-25NiCr etc in magnitudine 10-30um, 10-45um, 20-59um pulveris etc, sarcina 25kg in sacculo plastico cum tympano ferreo extra.

Scelerisque Spray Pulvis Cemented Carbide Hard-surfacing Pulvis

| Nec. | Item | Standard Specification | ||||||

| 1 | Gradus | TC % | Co% | Cr% | Ni% | Fe% | O % | |

| 2 | TSP42 | WC-12Co | 5.2-5.6 | 11.5-12.5 | - | - | ≤1.0 | ≤0.5 |

| TSP42D | WC-12Co | 5.2-5.6 | 11.5-12.5 | - | - | ≤0.15 | ≤0.5 | |

| TSP43 | WC-17Co | 4.7-5.2 | 16.5-17.5 | - | - | ≤1.0 | ≤0.5 | |

| TSP43D | WC-17Co | 4.7-5.2 | 16.5-17.5 | - | - | ≤0.15 | ≤0.5 | |

| TSP45 | WC-10Co4Cr | 5.2-5.6 | 9.1-10.1 | 3.0-4.5 | - | ≤1.0 | ≤0.5 | |

| TSP45D | WC-10Co4Cr | 5.2-5.6 | 9.1-10.1 | 3.0-4.5 | - | ≤0.15 | ≤0.5 | |

| TSP46D | WC-9Co5Cr1Ni | 5.1-5.8 | 8.5-9.5 | 4.5-5.5 | 0.8-1.2 | ≤0.3 | ≤0.5 | |

| TSP47D | WC-10Ni | 5.3-5.8 | - | - | 9.0-11.0 | ≤0.2 | ≤0.5 | |

| TSP48D | WC-20Cr3C2-7Ni | 5.8-6.4 | - | 20-23 | 6.0-8.0 | ≤0.5 | ≤0.5 | |

| TSP49D | Cr3C2-37WC-18NiCoCr | 7.8-9.4 | 3.0-4.0 | 39.5-42.5 | 10.5-12.5 | ≤0.5 | ≤0.5 | |

| TSP51D | Cr3C2-20NiCr | 9.7-10.7 | - | Libra | 15.0-17.0 | ≤0.15 | ≤0.5 | |

| TSP52D | Cr3C2-25NiCr | 9.1-10.1 | - | Libra | 19.0-21.0 | ≤0.15 | ≤0.5 | |

| TSP91D | WC-12Ni | 5.2-5.6 | - | - | 11.5-12.5 | ≤0.2 | ≤0.5 | |

| TSP92D | WC-17Ni | 5.0-5.3 | - | - | 16.5-17.5 | ≤0.2 | ≤0.5 | |

| TSP93D | WC-15NiCr | 5.0-5.4 | - | 2.5-3.5 | 11.5-12.5 | ≤0.5 | ≤0.5 | |

| 3 | Densitas | WC Based | Apparens densitas ≥4.0 g/cm3 | |||||

| Cr3C2Fundatur | Apparens densitas TSP49D ≥2.5g/cm3, TSP51D TSP52D ≥2.0 g/cm3 | |||||||

| 4 | Magnitudo | μm | 53-20 | 45-20 | 45-15 | 45-11 | 38-10 | 30-10 |

| Fluunt Rates/50g | WC Based | ≤18 | ≤18 | ≤18 | ≤18 | ≤18 | ≤30 | |

| Cr3C2Fundatur | - | - | - | - | - | - | ||

| 5 | Frumentum Morphologiae | TSPXXD est sphaericus vel fere sphaericus ab agglomerato et Sinteredo | ||||||

| 6 | stipare | 25kg aut 50kgs in plastic peram cum ferro tympanum foras | ||||||

Procurement Tips

- Sample Available in Request

- Salus Delivery bonorum per HEMERODROMUS / Aeris / Mare

- COA/COC Quality Management

- Secure & Convenient Pack

- Consociatione Nationum Latin sarcina Available Upon Request

- ISO9001:2015 Certified

- CPT/CIP/FOB/CFR Termini By Incoterms 2010

- Flexibile Payment Termini T/TD/PL/C Acceptabilis

- Plena dimensiva post-Sale Services

- Qualitas recognitionis per Sate-of-the-es facilius

- Rohs / SPATIUM Ordinationibus Approbatio

- Pacta Non Aperiri NDA

- Non-Conflictu Mineralis Policy

- Iusto Environmental Management Review

- Socialis Officia Plenitudo

Scelerisque Spray in pulverem

Durus-surfacing pulveris

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu